Pre-Press

The pre-press procedure includes the manufacture of a printing plate, image carrier or form, ready for mounting on a printing press, as well as the adjustment of images and texts or the creation of a high-quality print file.

Output devices

- 1 Creo Trendsetter Quantum F 3244 (8-up Thermal CtP system)

- 1 Fuji Luxel T9500 (8-up Thermal CtP system)

- 1 Screen Tanto DTR-5120 (8-up film recorder)

Proofing devices

- 2 Epson Stylus Pro, 1 Konica Minolta C6000

Sample Making

- Die-less cutting and creasing table for quick sample making & short production runs

Scanners

- Flat-bed scanner

Software

- All designing software

Press

Complimenting the recently attained printing machinery, Maxcomm possesses a Press section, where manpower work around the clock to implement the client’s impression and aspirations using the latest techniques available in the printing industry.

Komori Lithrone S729

- Size: 20.85in x 29.5in

- Color: 5 color

Komori Lithrone 240

- Size: 20.85in x 29.5in

- Color: 2 color

Heidelberg

- (5 color + Coater) 2 nos

- Sheet - fed with a maximum printing speed of 10,000 impressions per hour

Polar 115 3 nos

- Fully computerized paper cutting machine

Finishing

Cold Foiling

- Transferring highly detailed patterns in foil without the need for a stamping block

Spot UV coating

- 3 Sakurai and 1 Proteck screen printing machines for spot application of gloss, matte, raised and textured UV finishes

Hot Foiling

- 4 automatic foiling machines in various sizes with foil-saver technology from Germany and Italy (manual machines also available for short runs)

Laser Cutting

- 2 Machines from SEI (Italy) for high-speed and intricate laser cutting of materials upto 4mm thick

Embossing

- Multiple embossing machines

Binding

Folding machines

- 7 folding machines from Stall, GUK, Shoei and Horizon with up to 6 parallel and 3 cross folding capabilities

Saddle-stitching (Centre-pinning)

- 2 Sankoh (Japan) pinning and three-knife trimming machines with up to 7 form gathering stations

Section-sewing

- 2 automatic section-sewing (Smythe-sewing) machines from Meccatronica Aster, Italy

Perfect Binder

- 2 auto-perfect binding machines from Kolbus (24-clamp) and Muller-Martini (4-clamp)

3-Knife Trimmer

- 2 programmable trimming machines for three-side cutting of book blocks from Kolbus and Horauf (Germany)

Packaging Conversion

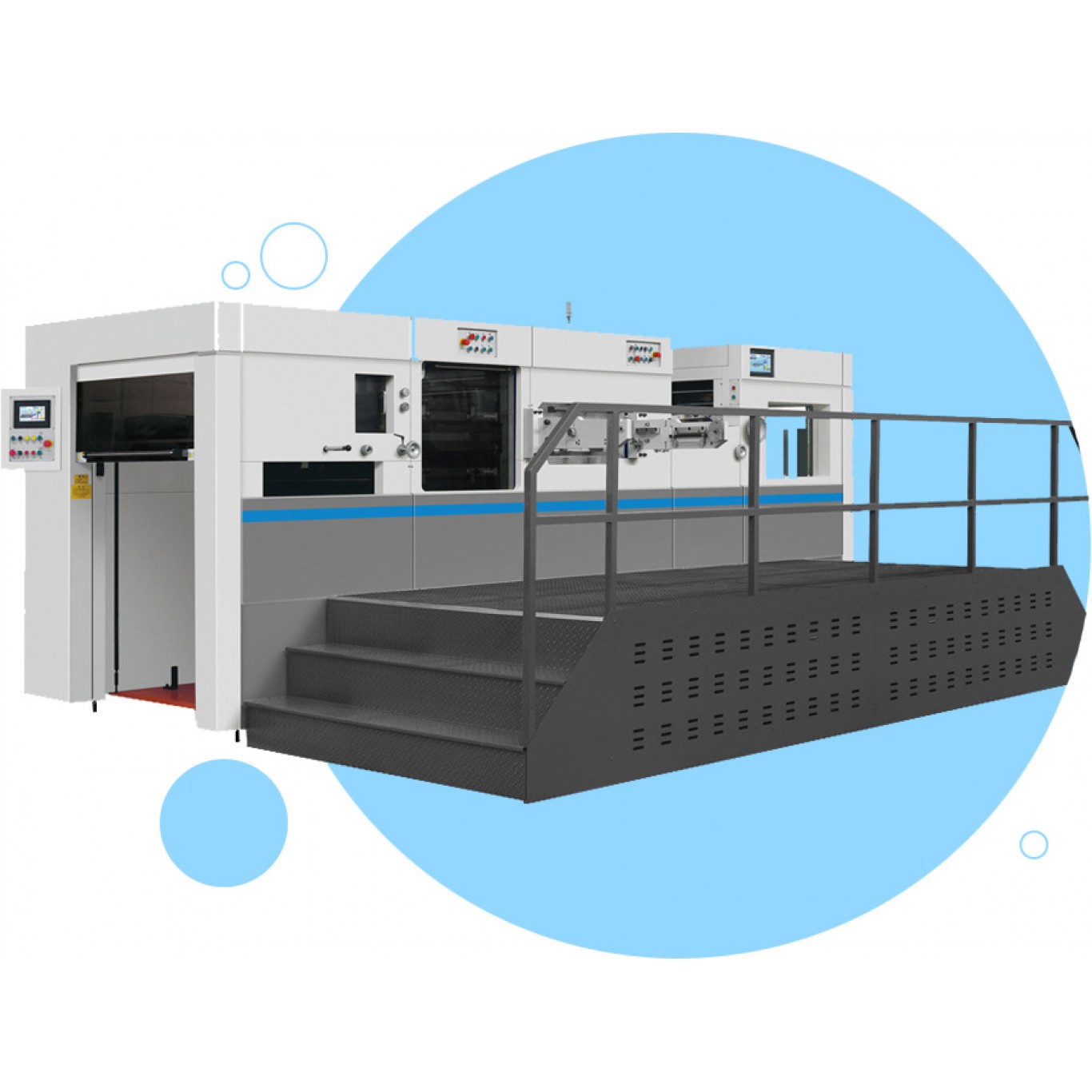

Auto-platen die-cutting

- 5 Fully automatic platen die-cutters with stripping – from Sanwa (Japan)

- Sugano (Japan) and Iijima (Japan)

Stripping Machines

- 2 Auto-stripping machines from Kawahara, Japan

Folder-gluers

- 4 folder-gluers capable of pasting tuck-in, crash-lock and 4-corner boxes from Bagempam

Sheeters

- 2 Sheeters – 1 fully automatic machine from China, and a manual sheeter of Indian make for conversion of paper and board from reels to sheets

Rigid box making line

- Semi automatic rigid box making line (box formation & outer liner pasting)

E-Flute pasting

- Registered Board-to-Fluting paster from Meigwong, China

Manual die-cutting

- 4 manual die-cutting machines

Window Patching Machine

- Fully automatic window patching and 360° window pasting machine from France